For many Star Wars fans, the lightsaber is a symbol of hope. It’s the elegant weapon of a more civilized age that can cut through blast doors or enemies and even predict and deflect incoming blaster bolts with the Force.

But how exactly does a lightsaber work? And how do Jedi build their sabres?

Savi’s Workshop

Since the opening of Galaxy’s Edge, one element has stood out among guests: building a lightsaber. Visiting Savi’s Workshop in Black Spire Outpost on Batuu allows guests to create a unique version of the iconic weapon. For quality Star Wars lightsaber, check this out!

When you arrive, a Gatherer will welcome you into the workshop and begin to explain the experience. The first decision you must make is what colour kyber crystal you want. This will determine your lightsaber’s blade colour. You can choose from red, blue, green, or purple.

Then, the Gatherer will show you a tray that contains components for your lightsaber hilt. You can select two options for the four hilt parts: pommel caps, emitters, and activation plates/switches. You will only be allowed 14 people into Savi’s at a time, which makes this experience very intimate and immersive. You can also build a lightsaber at Tatooine Traders, but it isn’t as high-end of an experience.

The Gatherers

The Gatherers are a group of droids specializing in collecting and building lightsabers. They usher players into a covert workshop packed with unusual parts, whimsical pieces and miscellaneous memorabilia from far-flung corners of the galaxy. Under their guidance, players can bring their hilts to life through the power of kyber crystals. For quality Star Wars lightsaber, check this out!

Each hilt features a different theme, forged from salvaged scraps of the Sith homeworld, fallen Jedi temples and crashed starships. Hilt materials also bear mysterious motifs and inscriptions that reconnect users with the ancient wellspring of The Force.

The Gatherers can build lightsabers with extreme precision, paying attention to blade colour, sound effects and more. However, their weapons are not just collector’s items but are designed for thrilling duels.

The Check-In Process

When you arrive for your experience, you’ll be escorted to Savi’s Workshop, a series of rooms within Black Spire Outpost. A group of Cast Members (“Gatherers”) will greet you with a dramatic telling of lightsaber history and lore.

Once inside the workshop, you’ll be at one of several build stations. The Gatherers then explain the four hilt styles and help you decide which is best.

Next, you’ll pick a kyber crystal for your blade. The Gatherers will ask you to close your eyes and envision which colour crystal you want. Once you’ve chosen a crystal, the assistants will let you start piecing together your hilt. In the end, you’ll receive a nice padded carrying case that will help protect your sabre on your trip home. And don’t worry — the sabre can go through airport security in a padded sheath, just like any other carry-on luggage.

The Experience

Once you enter the workshop, your lead Gatherer will greet you and explain the role of the Gatherers, which is to forge lightsabers out of “junk” collected from abandoned starships and hidden planets. For quality Star Wars lightsaber, check this out!

You’ll begin your build by choosing your cyber crystal, which imbues your lightsaber with energy. You’ll be given a cloisonne pin (that you get to keep) to designate which hilt style you would like to select for your custom lightsaber.

You’ll mix and match light-side and dark-side components as you create your lightsaber from scratch, making it unique. Once you’re finished, your Gatherer will assist with securing your lightsaber to its hilt.

You can take your lightsaber home in a padded sheath (though we suggest leaving it in the hilt for air travel). Your Gatherer will also give you information on how to maintain your sabre. They will tell you that a new crystal can be purchased for a small fee, so you can replace yours if it becomes damaged or worn out.

What is a Lightsaber?

A lightsaber is a weapon of the Jedi and Sith. It is a symbol of peace and justice and a deadly weapon of the dark side.

Lightsabers are hilts that contain several vital components, including a power cell or energy core, a focusing ring and a blade emitter.

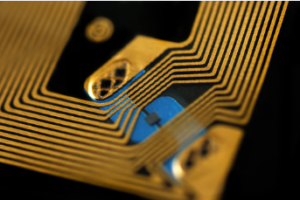

Unlike barcodes that require a direct line of sight to read, RFID technology automatically scans tags as they move throughout facilities. It eliminates the need for employees to manually scan and count inventory, which reduces errors and saves time. Plus, it allows employees to focus on other tasks and improves productivity.

Unlike barcodes that require a direct line of sight to read, RFID technology automatically scans tags as they move throughout facilities. It eliminates the need for employees to manually scan and count inventory, which reduces errors and saves time. Plus, it allows employees to focus on other tasks and improves productivity.