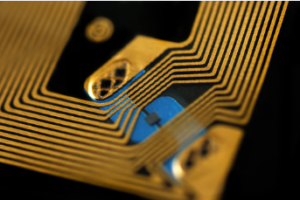

For businesses focused on supply chain management, RFID reduces management times and helps improve processes. That is because RFID can read data from long distances, even if there is no direct line of sight.

This streamlined tracking allows teams to spend less time on manual tasks and increase productivity. The RFID tracking device benefits include:

Increased Accuracy

Unlike barcodes that require a direct line of sight to read, RFID technology automatically scans tags as they move throughout facilities. It eliminates the need for employees to manually scan and count inventory, which reduces errors and saves time. Plus, it allows employees to focus on other tasks and improves productivity.

Unlike barcodes that require a direct line of sight to read, RFID technology automatically scans tags as they move throughout facilities. It eliminates the need for employees to manually scan and count inventory, which reduces errors and saves time. Plus, it allows employees to focus on other tasks and improves productivity.

Real-time tracking is another critical benefit of RFID asset tracking. This capability enables faster inventory counts, shipment verification, and enhanced logistics management that lead to cost savings, reduced stockouts and improved customer service. Additionally, RFID provides a wealth of data about operational processes, physical facilities, supplier performance and even consumer demand that can be used to optimize operations and improve overall supply chain performance.

Keeping track of high-value assets can be challenging for many businesses, whether it’s components on an assembly line, products being shipped out the door or industrial equipment that needs to be checked in and returned. And it only takes one missed item to add up to a major financial hit. For example, the American Auto industry replaces lost reusable packaging at a cost of $750 million per year and job site theft costs Construction companies $1 billion a year.

Reduced Labor Costs

The ability to automate inventory processes by reducing the need for manual data entry and minimizing error is another major benefit of RFID. The technology can also help reduce costs by eliminating the need for specialized hardware such as barcode labels, scanners and handhelds. It reduces both hardware and operational costs, resulting in a rapid return on investment.

Improved inventory management means more accurate forecasting, faster cycle counts and automated reordering at safety stock levels. It also means that customers can receive the products they need when they want them, increasing satisfaction and loyalty.

Source tagging allows manufacturers to track inventory as it moves from one area of the plant to another, providing unrivalled visibility and control. It can also be used to reduce shrinkage by detecting items that are not being paid for (shoplifting or employee theft) and by restricting access to merchandise that has been marked for sale but not shipped. RFID can also be used to verify inspection dates and locations of equipment and vehicles, helping companies meet regulatory or insurer requirements. It helps prevent damage and downtime while ensuring that assets are available when needed.

Increased Productivity

Inefficient tracking methods lead to wasted labour efforts, supply chain disruptions, and unwanted delays in product delivery. The best way to prevent these unnecessary hiccups is through effective asset management and monitoring that’s offered by RFID technology.

With RFID, tracking is automated, allowing teams to spend less time manually scanning and logging inventory movements, reducing overhead costs. Plus, fewer mistakes are made when tracking with RFID because the system eliminates human error in data entry.

The accuracy of RFID also extends to the actual tracking of items, making it much easier to know exactly what is in stock and when to order more. This boost in productivity means a business can avoid wasteful purchases and save money on storage space.

Lastly, an RFID tracking device offers an advantage in optimizing warehouse layouts with real-time data about what products move fastest, where there are bottlenecks and other critical insights. These data points can be used to reconfigure warehouse layouts, enabling employees to access the most in-demand items more quickly for increased productivity.

Moreover, RFID tools can be scanned at any location and don’t require direct line-of-sight to read tags, which enables companies to track their assets in more places than before. It is particularly beneficial for companies that own or lease expensive assets like test equipment, transport packaging, computer tech, and field vehicles, as replacing these expensive pieces of gear can cost them big bucks if they’re misplaced or stolen.